ASRS

Automated Storage and Retrieval System (ASRS)

-

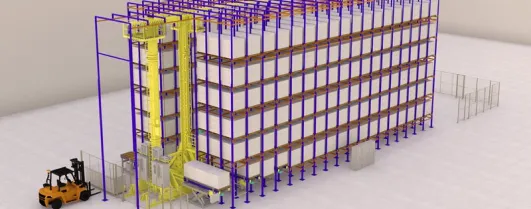

Modern technologies like automated storage and retrieval systems (ASRS) will move and store items in the high-bay warehouse of the cold storage facility.

-

Temperature-controlled warehouses make warehouse management harder since ordinary distribution equipment can't handle it. We can automate your manual storage, distribution, and order picking, saving staff from deep freeze and enhancing speed and accuracy.

-

ASRS are a great technique to maximize corporate space. Metraco has collaborated with ASRS installers in Singapore.

Discover how implementing an ASRS system can revolutionize your business operations.

Due to its complexity and challenges, we are confident in producing tremendous results throughout the last years

in building ASRS cold room requires specific expertise and technological understanding.

Recover of Floor

Recover of Floor Space / expand

storage capacity

Speed up operations

Speed up operations & Increase

Productivity

Picking Accuracy /

Picking Accuracy / Reduce picking

errors

Ergonomic Delivery

Ergonomic Delivery

Types of ASRS in Singapore: Customizable Solutions for Customer Requirements

Singapore has a number of Automated Storage and Retrieval Systems (ASRS) that can meet the needs of its

customers. You can change these methods and use them separately or together to get the most out of them. ASRS

can be used in many settings, but it works best in warehouses that are well-designed.

1. Unit-Load ASRS

- Ideal for high-density pallet loading.

- Maximizes vertical space while minimizing the footprint.

2. Mini-Load ASRS / FX-Quad Series

- Supports maximum load capacities up to 300kg.

- Compatible with dense case storage, such as totes and case loading.

3. Micro-Load ASRS

- Suitable for various shapes and weights of buckets and carton cases.

4. Refrigeration/Freezing Type ASRS

- Controls temperature and humidity continuously.

- Keeps refrigerated and frozen goods fresh.

- Suitable for 0°C to -35°C rooms.

5. Hazardous ASRS

- Automatic storage and retrieval for worker safety.

- An explosion-proof stacker crane improves efficiency.

6. Mid Load ASRS

- ASRS works in Singapore's large industrial storage and factory cool rooms. Singapore has space limits, thus vertical space is needed. This reduces cooling capacity and saves power.

7. Horizontal Carousels ASRS

8. Vertical Lift Module (VLM) ASRS

9. Vertical Carousels ASRS

Installing a Cold Room Around ASRS in Singapore

Planning a cold room around an ASRS structure or warehouse is a meticulous process that demands precision and careful consideration. To ensure the success of such a project, several crucial factors must be addressed:

1 Temperature Uniformity: Cold room temperatures must be stable. Our professionals monitor room temperature regulation in every corner.

2 Heat Management: Cold room cooling must account for ASRS machine and computer heat. We specialize in temperature control systems.

3 Size and Space: ASRS structure, traffic flow, and inventory sizes affect cold room layout. Our solutions are customized.

4 Quality Materials and Equipment: Our cool room installations employ only the best materials and equipment to protect your goods.

ways ASRS can reduce costs and improve cold chain performance

1. Optimized Space Utilization

ASRS systems use space efficiently, reducing the building footprint and floorspace requirements by up to 25%.

2. Energy Savings

ASRS coldroom systems offer long-term cost savings through energy efficiency, reduced labor, and faster order fulfillment.

3. health & safety benefits

Calibrated machines in the ASRS warehouse enhance safety, reduce cold environment exposure, and boost overall productivity.

4. Faster Order Fulfillment

Automation speeds up order processing, especially for fast-moving products, enhancing efficiency.

5. Improved Work Environment

ASRS eliminates the need for employees to work in harsh cold environments, reducing turnover and increasing productivity.

6. Reduced Damage

Automation reduces accidental damage to products and equipment, improving operational efficiency.

7. Efficient FIFO Stock Rotation

Using FIFO in cold storage centers ensures error-free order picking and fresh, accurate inventory management.

8. Inventory Tracking

ASRS ensures precise inventory tracking and location accuracy, increasing security and eliminating errors.

9. Control of “quarantined” products

With ASRS, inventory that is quarantined for whatever reason is electronically locked-in and not available for picking.

10. Enhanced Product Quality

Optimal spacing in ASRS cold storage units maintains food product quality by ensuring consistent temperatures and preventing spoilage.

11. Customer Service Excellence

Customers expect accurate orders and even the occasional error can badly damage the cold storage provider’s reputation and relationship with their customer.

A Solution For Gaining a Competitive Edge

Growing Demand

The need for refrigerated storage is rising due to fresh produce and frozen meal market growth.

Automation Benefits

Automated storage (ASRS) offers a competitive edge by reducing labor, enhancing service, and optimizing space.

Cost-Efficient

Lower automation costs make ASRS a smart investment for businesses.

Unlock Enhanced Efficiency and Cost Savings for Your

Refrigerated Storage Operations Today!

Head over to our Contact Us page and let's elevate your refrigerated storage solutions!

Contact Us